Concrete Pipe Mill High Speed Cropper System Design and Manufacture

The task was to design and manufacture a 27400N cropper with the objective of delivering a fast and effective way of cutting steel reinforcing bars on a perpetual basis over a lengthy time period. The use of online pumping was not suitable due to continuous pressure fluctuations and subsequently the system was designed with accumulator tanks in order to supply uninterrupted pressure and flow to the short stroke actuator. Additionally, fluid evacuation valves were installed on the actuator to enable effective cooling.

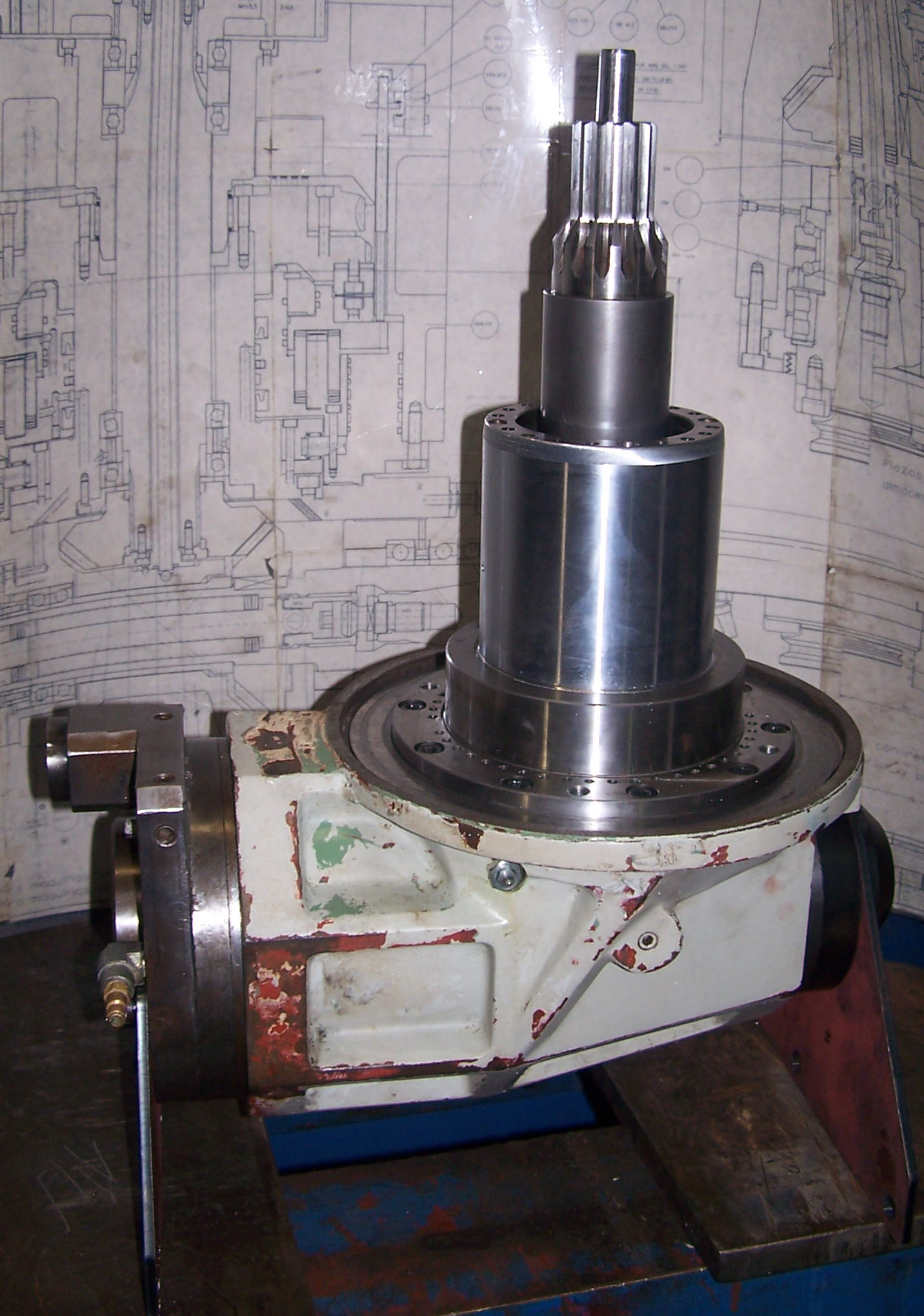

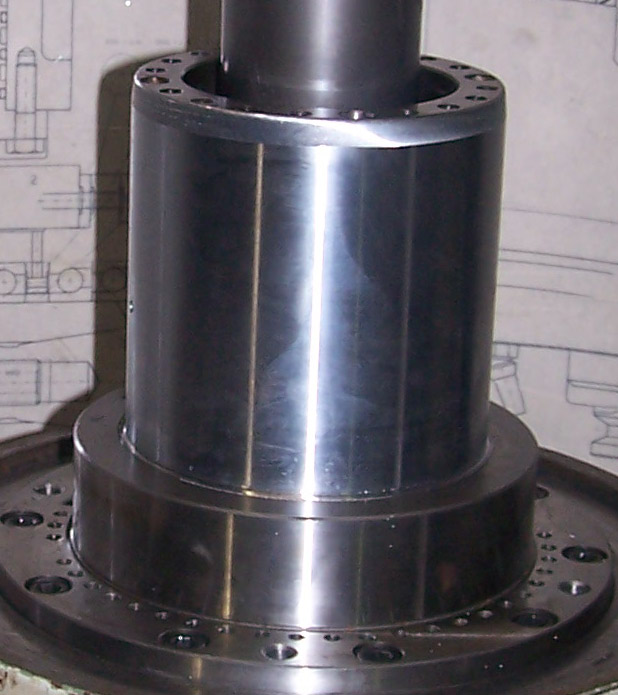

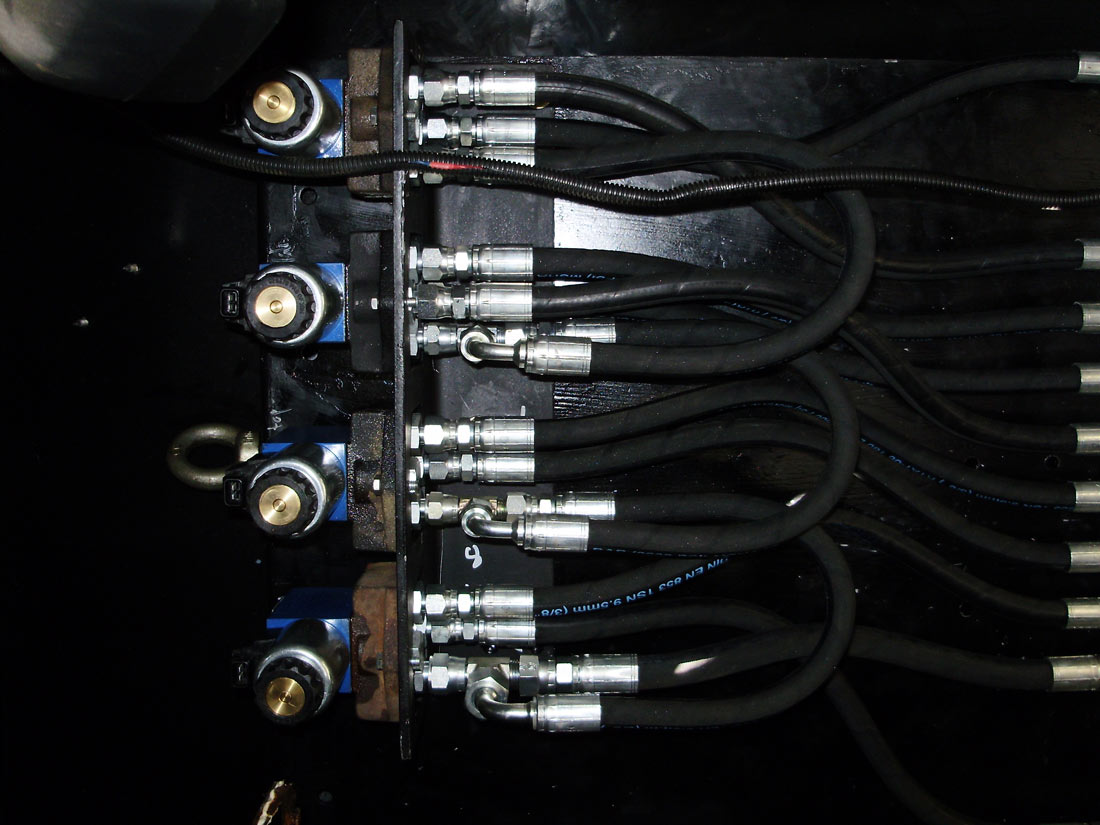

High Pressure Synchronised Jacking System Design and Manufacture

The system requirement arised from the need to remove capping from a concrete mould without damaging the pipe lips; as such, vibrating equipment could not be used. A 690bar synchronised jacking system was developed with an optimum angle so as to alleviate damage and utilised an efficient, high volume triple pump which enabled the cylinders to be to be synchronised within 10% Coal Loading Dock Diesel Tower Crane Drive System Design and ManufactureClient specifications required two 50 kW drive systems without the use of electro-hydraulic interfaces. A comphrensive drive system was developed within specifications whilst still delivering optimum performance and component utilisation.

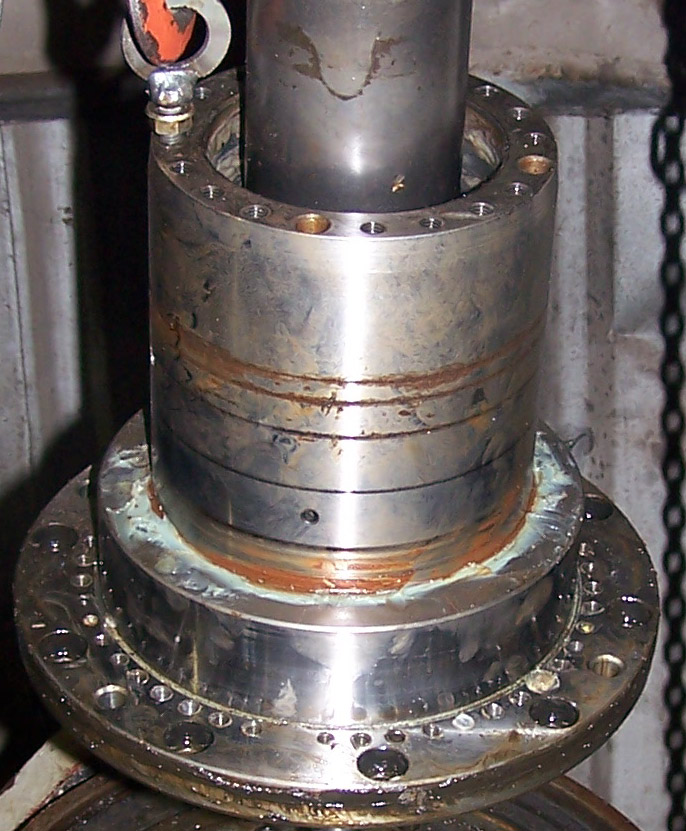

Cross City Tunnel Road Boring Header Maintenance

Operating in an extremely hostile environment, these tunnel cutting machines require intensive maintenance with the upmost care in ensuring all hydraulic systems are free from contamination. All components from acumulator tanks to valves and gearboxes were thoroughly inspected and serviced so as to mitigate contaminates and the potential for water ingress.

Marine Travel Lift Winch and Steering Maintenance

After diagnosis, we supplied and installed new hydraulic drive pumps and motors, and repaired leaking valves and cylinder seals. Upon testing, the travel lift performed to its original specifications.

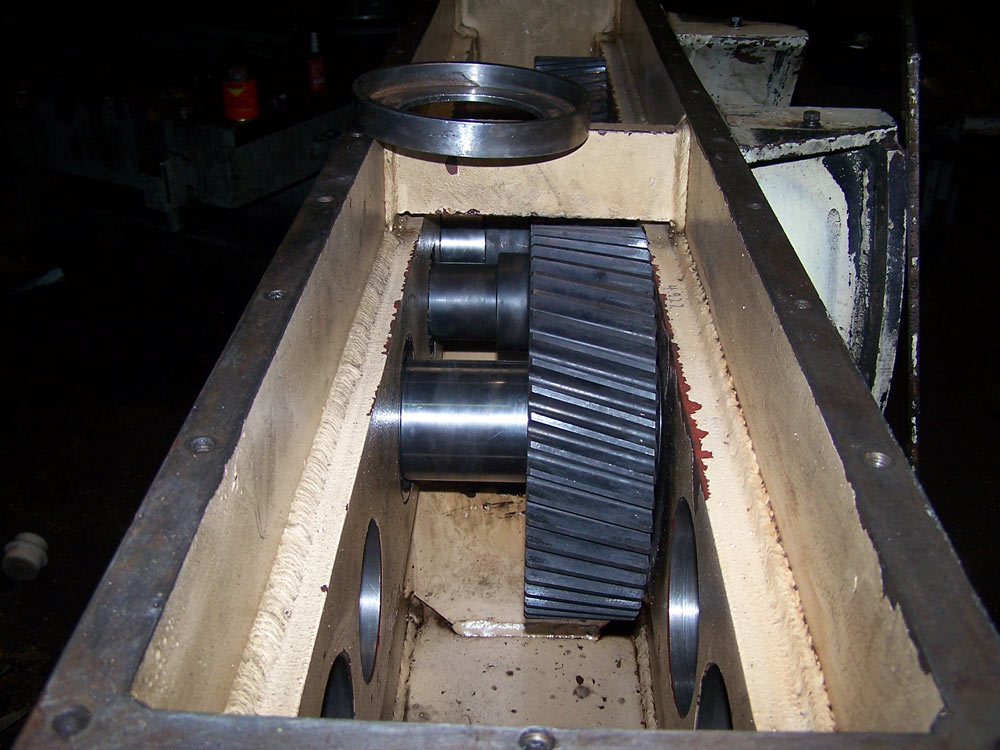

Webster and Bennett Repairs and Maintenance

These solid robust machines, designed and manufactured in UK, are still widely used in the metal working industry today and genuine parts are readily available.

Hydraulic Diagnostics run ongoing maintenance programs for clients ranging from regular servicing to retro fit filter systems to complex drive train remanufacturing.